Industrial Guther

Developing tailor-made

solutions to meet your needs

We are a company with 23 years of experience in industrial machining, committed to quality and service. We position ourselves as one of the leading options for the electronic and industrial maquila industry in the western part of the country, the Mexican Silicon Valley.

Driving innovation and quality in every component

Excellence in Industrial Machining Solutions

At Industrial Guther, we have been leaders in manufacturing machined industrial components for over 20 years. We have become a trusted partner for high-tech and manufacturing industries in Mexico.

Our focus on innovation and commitment to quality allows us to provide tailored solutions to our customers.

Our Services

Services

At Industrial Guther, we provide comprehensive solutions for cutting, machining, and finishing industrial parts, ensuring maximum precision, quality, and efficiency in each process.

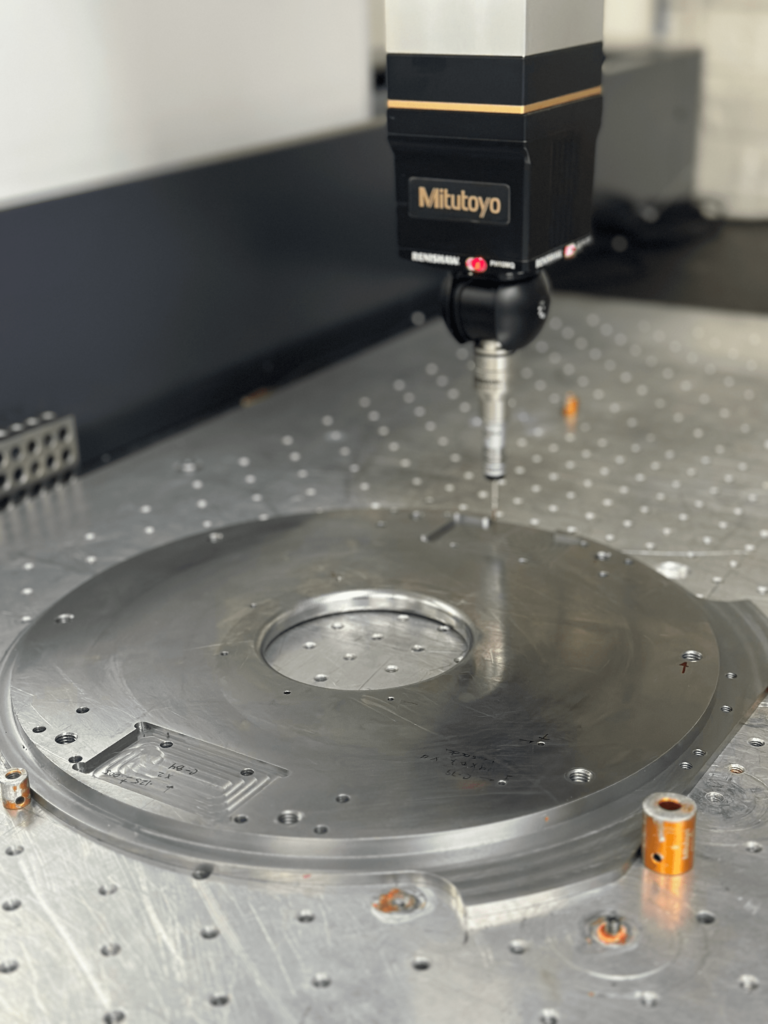

Machining

We offer custom part manufacturing services, using high-precision CNC technology to ensure quality and accuracy in every process.

Cutting

We offer cutting services both as an auxiliary process in our machining work and as subcontracting for our clients, ensuring precision and quality in every operation.

Finishes

We have a variety of processes to offer complete solutions to our clients, backed by our business relationships and experience in finishing applications.

Packaging, Pallets, and Crates

We offer tailored solutions according to our customers’ needs. We have specialized technical equipment for the development of packaging, special pallets with the necessary hardware and accessories to ensure safe shipping. Additionally, we manufacture crates to provide full protection for equipment, whether for telecommunications or medical equipment, ensuring its integrity during transport.

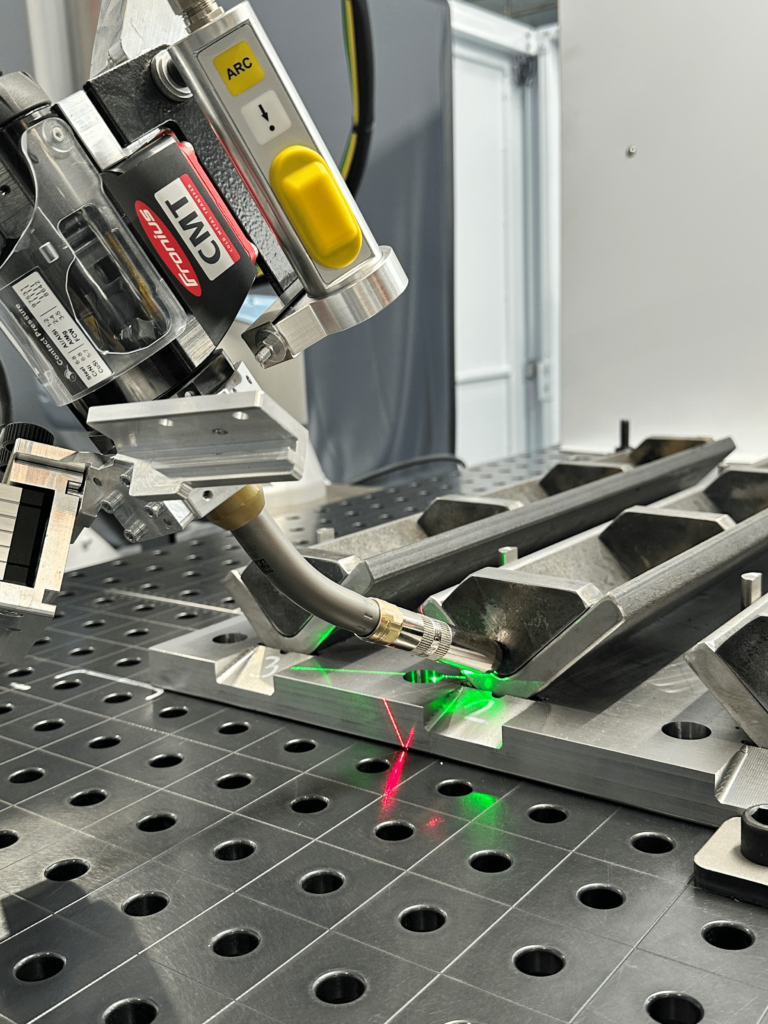

Robotic Welding Cells

We have a serial welding process capable of welding structural steel or sheet metal by cold welding, as well as aluminum, ensuring high precision and efficiency in every operation.

SMT Tools

We offer design and manufacturing services for tooling from Gerber files, physical samples, or reverse engineering. We adapt to the needs of your soldering, inspection, and cutting lines, ensuring precision and efficiency in each solution.

Where do our products go?

We serve various industries, meeting the specific requirements of each, including clean energy, medical equipment, semiconductor manufacturing equipment, data center infrastructure, telecommunications, and the furniture industry.

Clean Energy

We supply key parts for renewable energy projects, supporting the development of a sustainable economy

Data Centers

We provide essential components that ensure the optimal operation of the technological infrastructure of data centers

Semiconductor Equipment

We manufacture essential components for the semiconductor industry, meeting the highest technological standards

Furniture

We supply custom-made parts that ensure quality and durability in industrial furniture manufacturing

Telecommunications

We manufacture essential components for technological infrastructure, contributing to the development and expansion of communication networks.

Medical Equipment

We produce critical parts with high safety and precision standards for the medical industry

Our Clients

Precision Technology

Machined components with the highest precision to meet the most demanding standards of quality and performance.

Automation

Production with advanced technology, ensuring efficiency and consistency in every process.

We maximize the efficiency and performance of your industrial processes

Our Difference

At Industrial Guther, we specialize in the design and manufacturing of industrial components that not only meet but exceed precision and durability expectations. Our products are crucial in high-demand sectors, providing reliability and excellence in every detail.

Learn More About

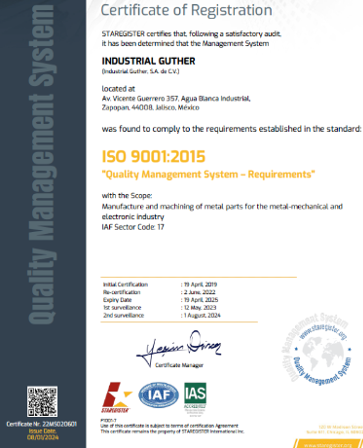

Our Certifications

At Industrial Guther, we are committed to excellence in each of our manufacturing and machining processes. This commitment is reflected in our ISO 9001:2015certification, an international standard that regulates quality management systems.

Industries

Our Blog

Latest Posts

Explore our latest posts and stay up-to-date with key industry trends. Discover innovations and how we are transforming the future with our services and products.

Evolution and History of Machining Processes

Machining is an essential process in manufacturing, used to shape solid materials through cutting tools...

What is G-Code in CNC Machining?

G-Code is a programming language used to control CNC (Computer Numerical Control)...

CNC Machining

CNC (Computer Numerical Control) machining is an automated manufacturing process that uses computers to control cutting tools

Find answers

F.A.Q.

Producción

We offer comprehensive solutions in machined parts, as well as laser cutting, bending, welding services, and the manufacture of specialized pallets and crates.

We have 20 machining centers with 3 and 4-axis capabilities, CNC lathes, cam lathes, and automated welding cells. Additionally, we have plasma and laser cutting equipment, as well as machinery for bending processes.

Our manufacturing capacity reaches up to 70,000 parts per month, distributed across our different work centers.

Yes, we adapt to each customer's needs, including the production of small batches. We also offer inventory management without additional cost.

Yes, we have experience in managing production increases and have dedicated teams to handle demand surges.

We offer a variety of finishes, including galvanizing, alodine, anodizing, nickel plating, sandblasting, tumbling, tinning, liquid painting, and powder coating.

Quality

Yes, we operate under a quality management system certified by ISO 9001:2015.

Yes, we issue Certificates of Conformity (CoC) for our parts and use materials that comply with regulations such as RoHS and REACH.

Each work order includes inspection records during the process, in accordance with the inspection plan. Additionally, we use properly calibrated measuring equipment to ensure the accuracy of our products.

Commercial

Our prices are determined based on production volume, ensuring competitiveness for both parties. We focus on establishing long-term business relationships.

Payment terms can be adjusted according to the customer's needs, considering the sales level. We also offer early payment discounts.

Delivery times vary depending on the complexity of each part. However, we can offer expedited delivery options, with or without additional cost.

We make deliveries with our own fleet or through carriers. We also offer the option of FOB delivery according to the customer's requirements.