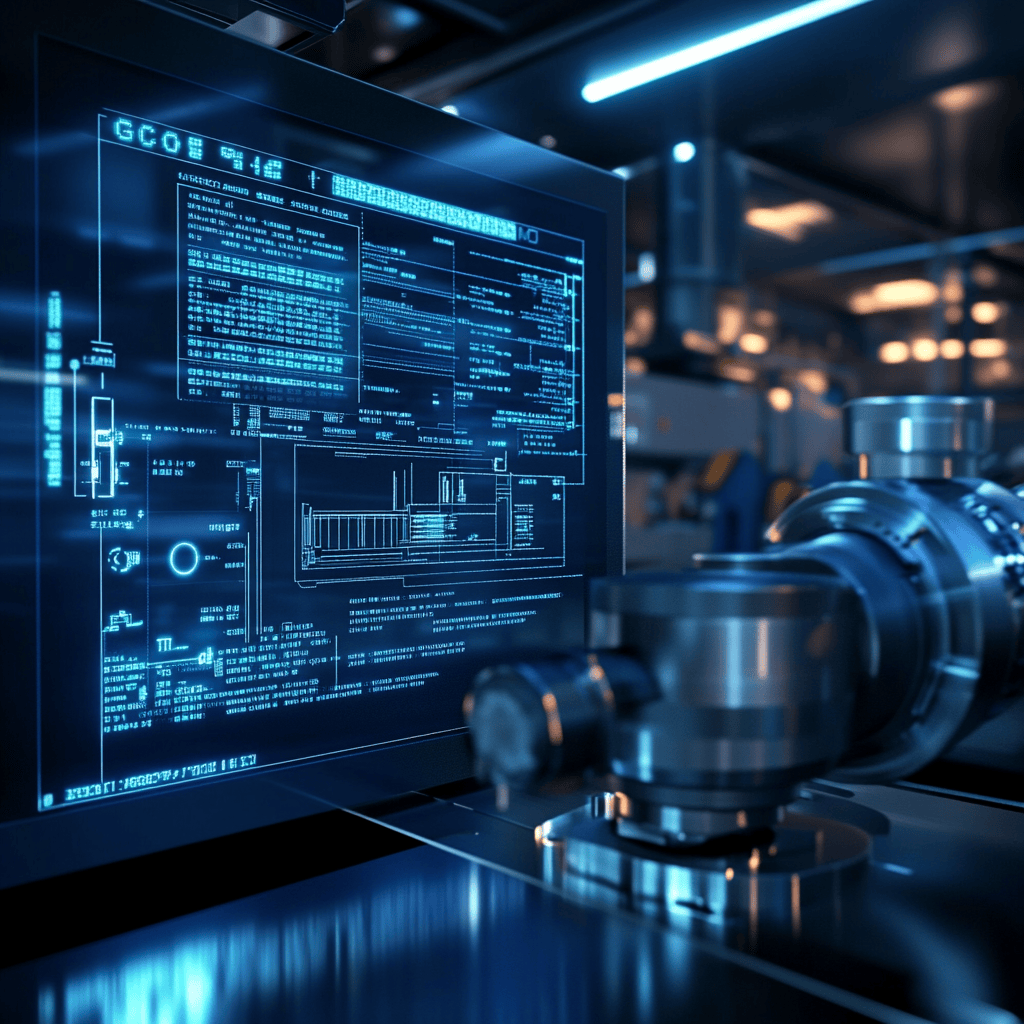

G-Code is a programming language used to control CNC (Computer Numerical Control) machines. Through specific commands, G-Code instructs the machine on movements, speeds, positions, and other essential machining operations.

How G-Code Works

G-Code consists of a series of sequential commands that the machine interprets and executes. Each line of code typically begins with a letter (G, M, F, S, etc.), followed by a number indicating the specific function to be performed.

For example:

- G00: Rapid movement without cutting.

- G01: Linear movement with cutting.

- G02/G03: Movimiento circular en sentido horario o antihorario.

- M03/M04: Encendido del husillo en sentido horario o antihorario.

- F100: Velocidad de avance en mm/min.

- S1500: Velocidad del husillo en revoluciones por minuto (RPM).

Importance of G-Code in CNC

G-Code is essential in CNC machining because it allows:

- Precision and repeatability: Defines exact paths for consistent cuts.

- Automation: Reduces human intervention and manual errors.

- Flexibility: Can be adapted for different materials and processes.

Applications of G-Code

G-Code is used in various industries to manufacture complex parts, including:

- Aerospace: Manufacturing of structural components and turbines.

- Automotive: Production of engine and transmission parts.

- Medical: Creation of implants and surgical tools.

Conclusion

G-Code is the fundamental language in CNC machine programming, enabling the production of parts with high precision and efficiency. Mastering it is key to optimizing manufacturing processes and improving the quality of final products.