Machines

- Home

- Machines

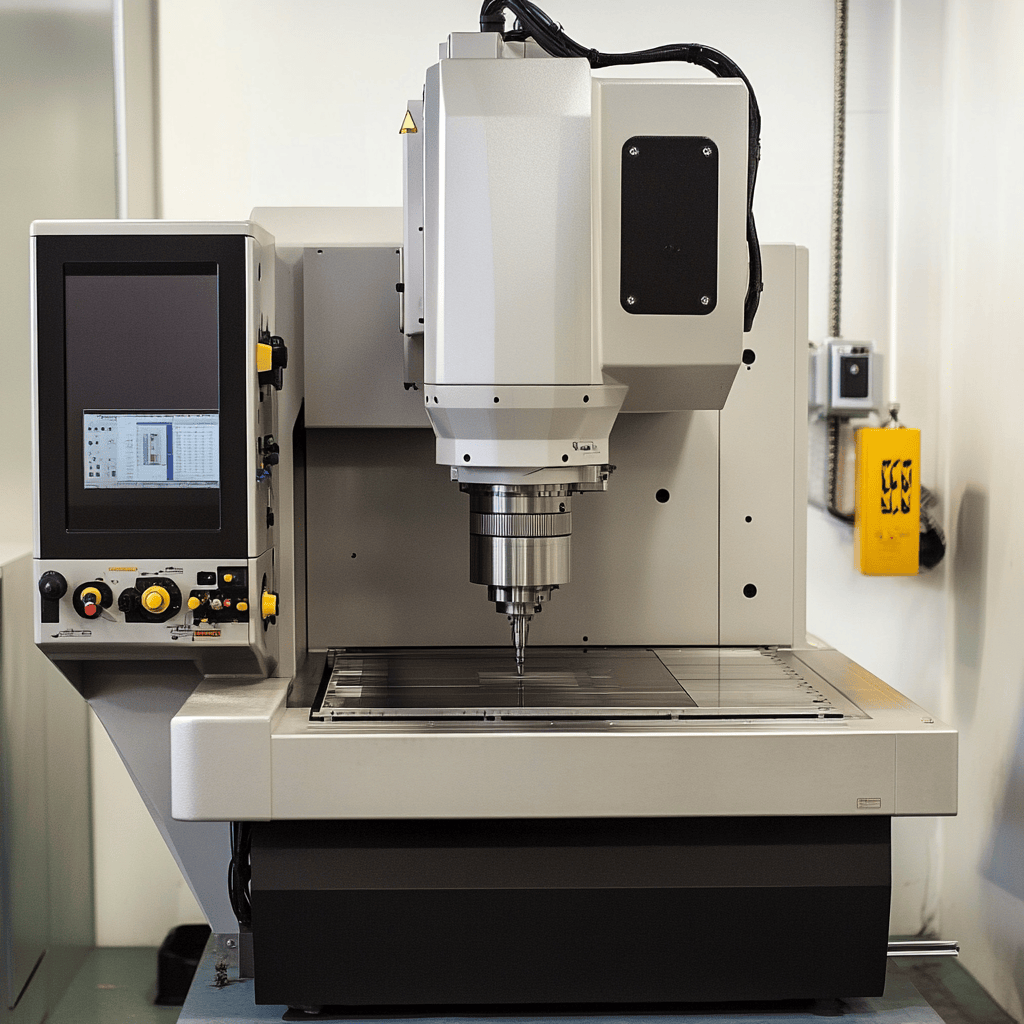

Vertical Machining Centers

We have a wide range of vertical machining centers designed to provide precision, versatility, and efficiency in manufacturing processes. We have 20 machines with capacities ranging from 580 x 420 x 508 mm to 1,016 x 508 x 635 mm, allowing for the manufacturing of pieces of various sizes and complexities.

These centers are equipped with up to 30 tools and operate with spindle speeds ranging from 8,100 RPM to 15,000 RPM, ensuring fast and high-quality production. They are ideal for a wide range of applications, including machining metals, plastics, and other industrial materials, offering flexibility to adapt to each customer’s specific needs.

- Number of machines: 20

- Capacity range: From 580 x 420 x 508 mm to 1,016 x 508 x 635 mm

- Tool capacity: Up to 30 tools

- Spindle speed: Between 8,100 RPM and 15,000 RPM

High Precision Lathes

We have 6 lathes ideal for performing high-precision turning operations. The lathes have a turning diameter ranging from 600 mm to 625 mm, allowing for the processing of a wide range of large-sized pieces.

Each of our lathes is equipped with 12 to 24 tools and operates at speeds up to 10,000 RPM, ensuring efficient and high-quality production. Additionally, we incorporate CAM lathes to optimize manufacturing processes, providing greater flexibility and control in programming complex, precision parts.

These lathes are ideal for working with different materials, from metals to high-resistance plastics, and allow for rapid adaptation to different production requirements. Their advanced technology ensures precision, efficiency, and reduced delivery times.

- Number of machines: 6 CNC lathes

- Swing diameter: Between 600 mm and 625 mm

- Number of tools: From 12 to 24 tools per lathe

- Spindle speed: Up to 10,000 RPM

- Integrated technology: CAM lathes for optimization and greater flexibility in programming

High Precision Profiling Machines

We have 3 profiling machines designed to provide precision and quality in the machining of complex profiles. We have 2 conventional profiling machines for standard jobs and a state-of-the-art CNC profiling machine with a spindle speed of 5,000 RPM, ideal for optimizing production times and ensuring uniform finishes.

Our profiling machines allow for the manufacturing of pieces with precise geometries in a wide variety of materials, offering efficient solutions for the manufacturing industry. Thanks to the integration of CNC technology, we can perform automated processes with greater repeatability and accuracy, ensuring quality and efficiency in every project.

- Number of machines: 3 profile machines

- Types: 2 conventional profile machines and 1 state-of-the-art CNC profile machine

- Spindle speed: Up to 5,000 RPM

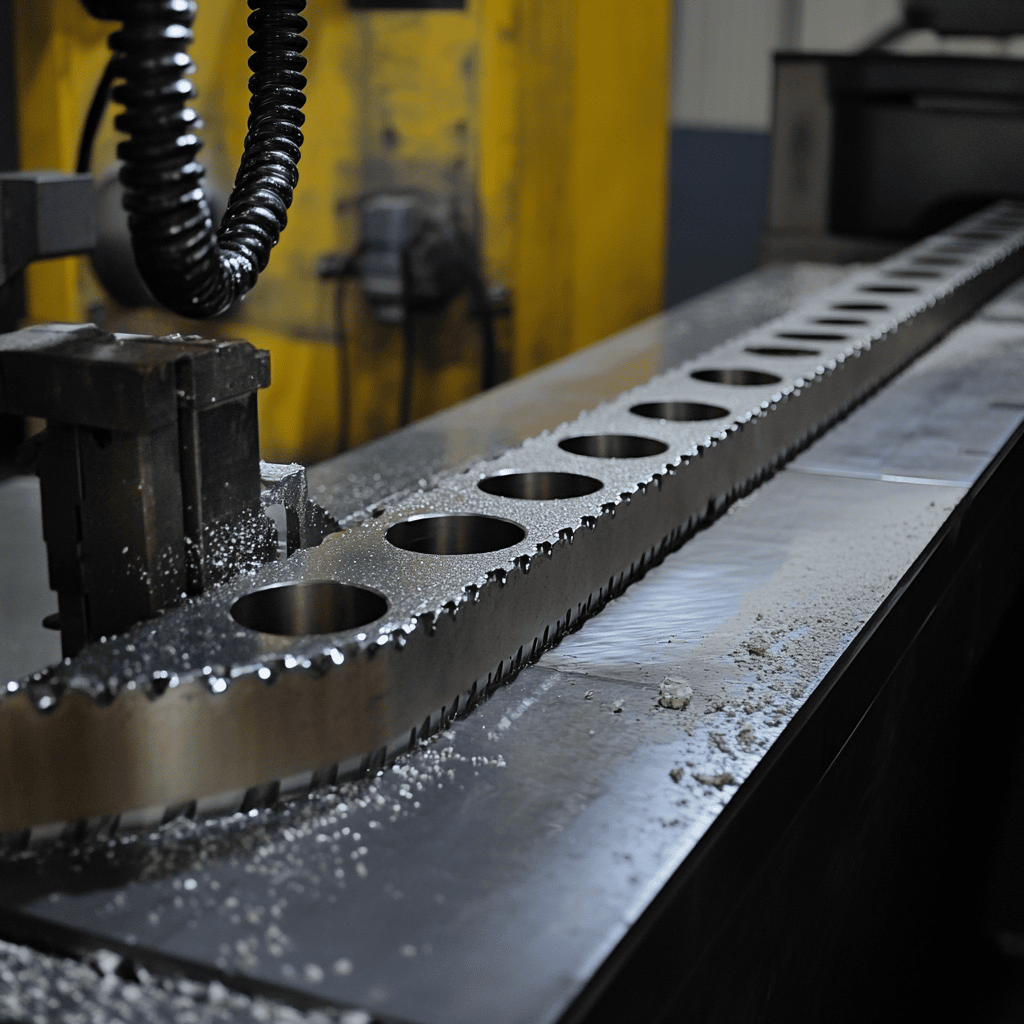

High-Capacity Band Saws

We have 4 high-precision band saws with a cutting capacity of up to 381 mm in diameter, ideal for efficiently processing materials in bars, tubes, and profiles. These machines provide clean and accurate cuts, optimizing production times and reducing material waste.

Our band saws are designed to work with a wide range of materials, including steels, aluminum, and engineering plastics, ensuring versatility and reliability in each process. Thanks to their robustness and precision, we guarantee uniform, high-quality cuts to meet the most demanding industry standards.

- Number of machines: 4 precision band saws

- Cutting capacity: Up to 381 mm in diameter

- Materials types: Steel, aluminum, and engineering plastics

- Applications: Cutting bars, tubes, and profiles

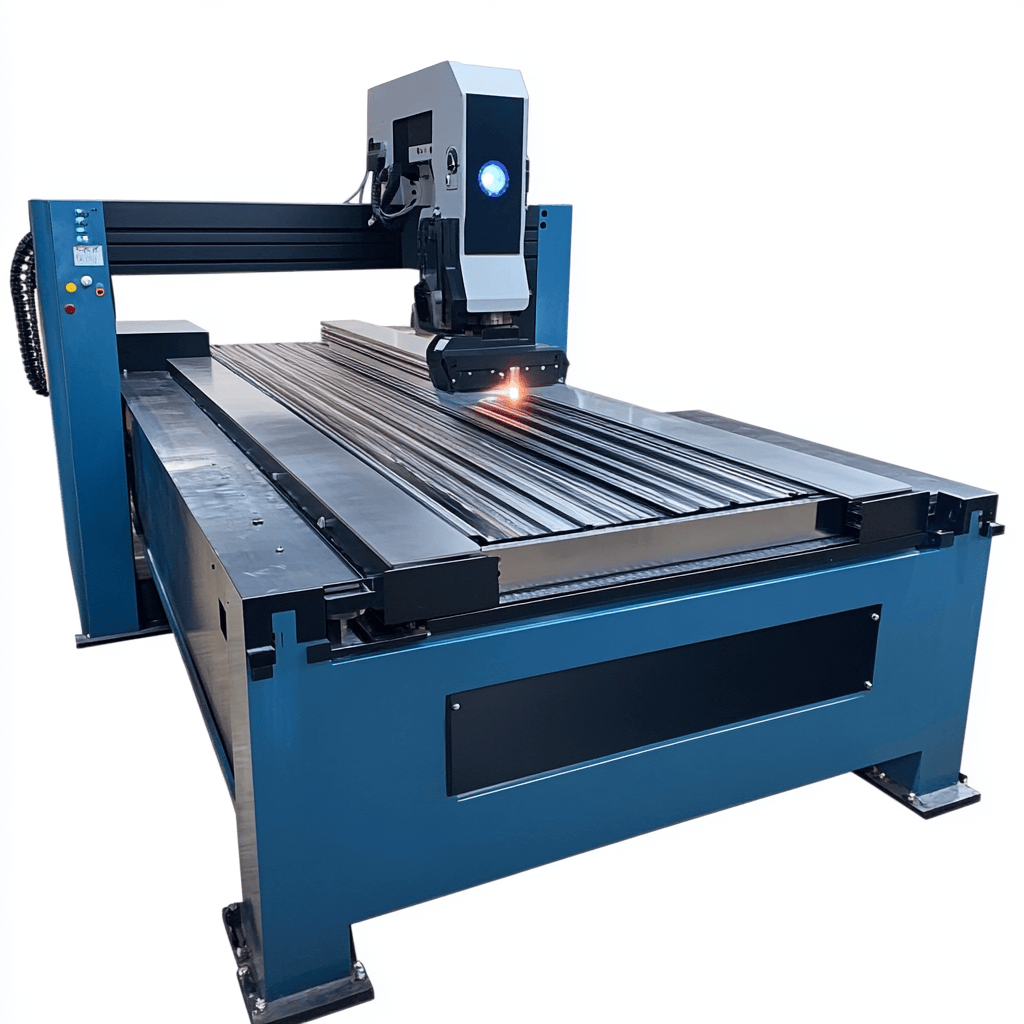

High-Precision Plasma Cutters

We have 2 CUTMASTER 152 plasma cutters with a power of 120A, designed to provide fast, precise, and high-quality cuts in various conductive materials. These machines allow continuous cutting in materials up to 19 mm thick and can process pieces up to 50 mm maximum thickness.

Thanks to their advanced technology, our plasma cutters guarantee clean edges, minimal deformations, and high production efficiency. They are ideal for industrial applications that require precision in cutting steels, aluminum, and other metals, ensuring a reliable and high-performance process.

- Number of machines: 2 CUTMASTER 152

- Power: 120A

- Cutting capacity:

- - Continuous cutting: Up to 19 mm thickness

- - Maximum thickness: Up to 50 mm

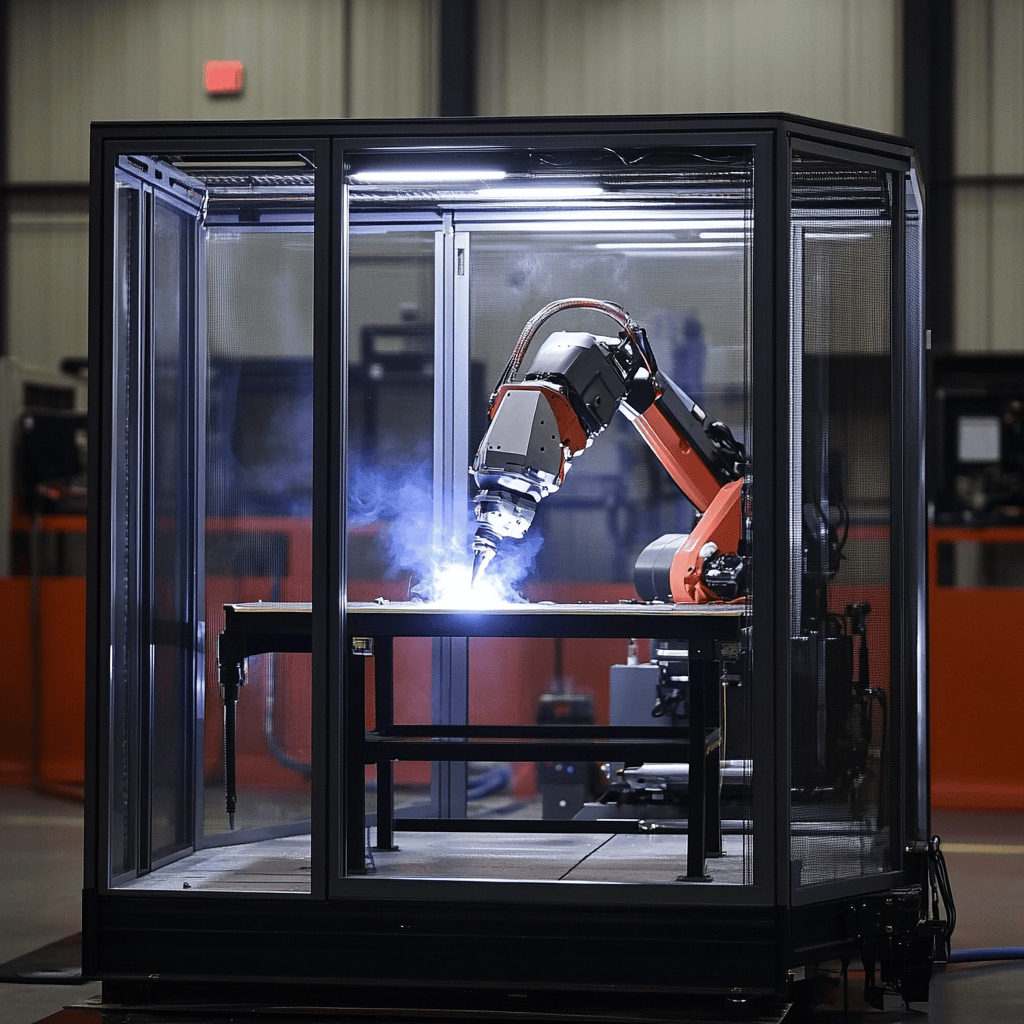

Robotic Welding Cells for Maximum Efficiency

We have have 2 state-of-the-art robotic welding cells designed to optimize welding processes with high precision and repeatability. These cells allow for automated arc welding, guaranteeing consistent joints, reducing production times, and improving the final product quality.

Thanks to their advanced technology, our cells are ideal for manufacturing metal components with high resistance and finish standards. Their flexibility and efficiency make them perfect for a variety of production runs, ensuring uniform and high-quality welding in each piece.

- Number of cells: 2 state-of-the-art units

- Welding type: Automated arc welding

- Key benefits:

- - High precision and repeatability in each weld

- - Consistent joints and improvement in final product quality

- - Reduced production time